Importing HTRI files

In the Heat Exchanger window, you have the ability to read the data of an Heat Exchanger straight from the thermal calculation with HTRI.

HTRI is the leading company producing software for thermal calculation of Heat Exchangers. HTRI is available separately from NextGen: to perform the procedure illustrate in this article, you need a valid license for the two softwares, and both shall be installed on the same computer.

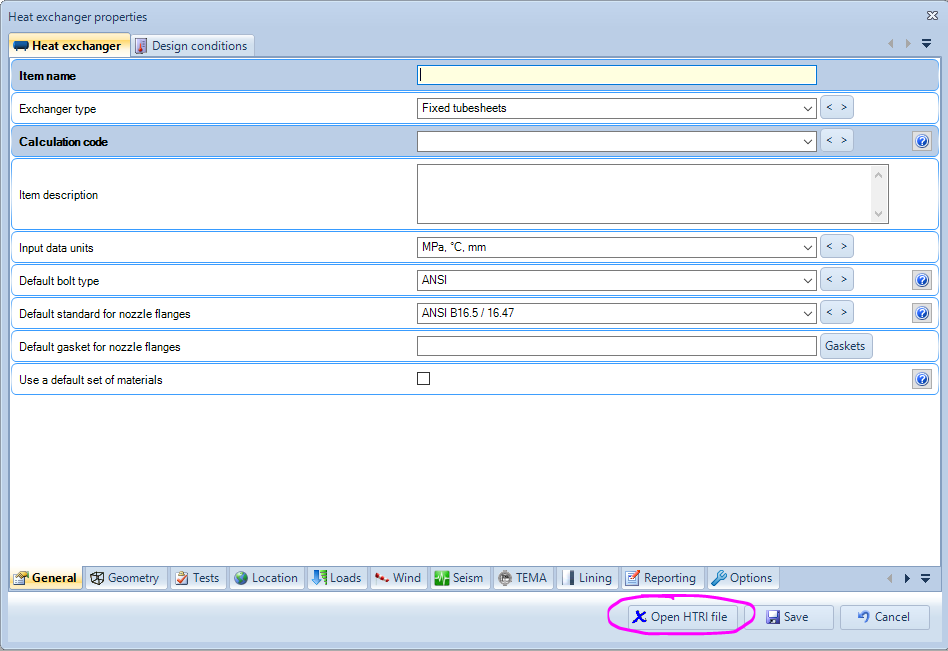

As soon as you create a new Heat Exchanger file, the "Import HTRI file" command is available. Just set the calculation code for the item, then proceed by clicking the import button.

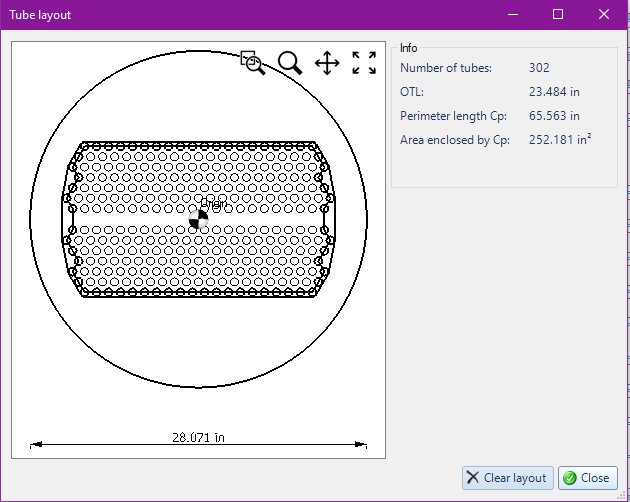

Select the file you want to import and wait a few seconds to let NextGen map said file with its own format. The tube layout window then appears, for you to check the main tubesheet parameters.

If everything is ok, you can proceed by closing the tube layout windows and saving the Heat Exchanger file.

What's being imported

NextGen tries to fetch as many data as possibile from the HTRI file. Not always all these data are available from the source file, so you should expect to find all the geometric data already set in HTRI after the import.

The main configuration of the exchanger is imported, including TEMA type and class, input units and design conditions.

Materials and gasket can also be imported. Materials are limited to a subset of ASME II, comprising aroung 300 commonly used materials.

As for the geometry, diameters and thicknesses of the front end, rear end and main shell are imported, as well as tubesheet dimensions and tube bundle geometry (including thickness, diameters, number of tubes, pitch, OTL, non-drilled areas).

One of the greatest advantages of this approach over a normal data entry is the fact that design and operating temperatures are coming straight from the thermal calculation: in some cases this is fundamental for a good mechanical design, since temperatures may affect a lot the thicknesses of the exchanger parts (e.g. in fixed tubesheets exchangers).

Complete list of all the fields that NextGen can import from HTRI

Below is the complete list of properties that can be imported by NextGen: what is actually imported depends, as previously specified, on the conditions of the input file and on the configuration of the exchanger.

Heat exchanger type (U-tube, fixed tubesheets, floating tubesheet)

Input units (metric or US customary)

Calculation code (ASME VIII Div. 1, EN 13445)

Description

Number of passes

TEMA compliance required and TEMA class (R, C, B)

Revision number and date

Shell side pressure and temperature

Shell mean temperature

Shell metal temperature at tubesheet

Shell side corrosion allowance

Shell side vacuum

Channel side pressure and temperature

Channel metal temperature at tubesheet

Channel side corrosion allowance

Channel side vacuum

Tubesheet design temperature

Tubesheet rim metal temperature

Tubesheet operating temperature

Tubes mean metal temperature

Front end type (A, B, C, N, D)

Front end diameters and thickness

Shell type (E, F, G, H, J, K, X)

Shell diameters and thickness

Tubesheet thickness

Tubesheet outside diameter

Tubes diameter

Tubes thickness

Tubes pitch

Tubes straight length

Tubes unsupported length

Tubes OTL

Number of tubes

Tubes pattern type (square, triangular)

Rear end type (L, M, N, P, S, T, U, W)

Materials for shell, tubes, front end, tubesheet, heads, covers, floating flange, rear end

Tubesheet flange gasket

I'm receiving and error while importing an HTRI file

From version to version, the structure of an HTRI file may vary a lot and this may lead to errors when trying to import a new file. Please get in touch with us to receive support on the matter.