Discover NextGen

Save time and money by adopting a simple, complete and design-oriented complete software solution.

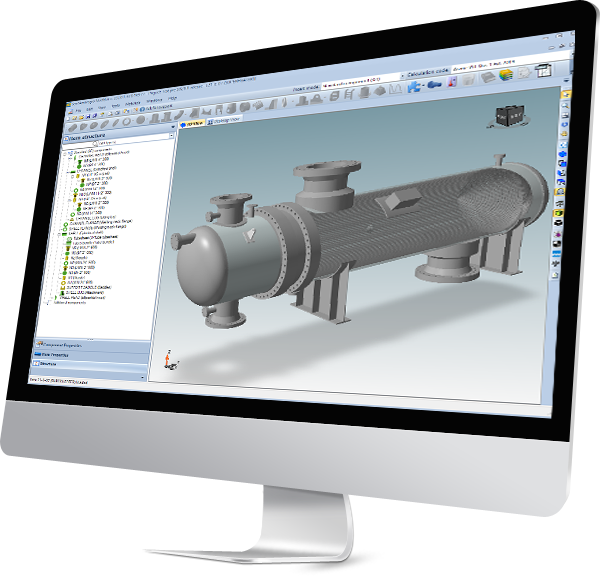

NextGen is a software for the design and validation of pressure vessels and heat exchangers according to the major international standards.

NextGen delivers the power of comprehensive engineering suites while focusing on agility and material savings: thanks to automatic thickness optimization (Usage Factor), our users can drastically reduce manufacturing costs without the need for time-consuming manual iterations.

One of the most appreciated features is the regulatory flexibility: NextGen makes it extremely easy to switch between different calculation codes for the same vessel. For instance, you can convert a project designed according to ASME VIII Div. 1 to EN 13445 with just a few clicks, reusing the entire geometric model and input data.

Along with the calculation against pressure it can check supports, taking into account loads like wind, seism and snow. To finish up, it is possible to evaluate local loads according to WRC bulletins, columns lifting and their structural integrity.

A large materials database is available, as well as flanges, pipes, curves, caps, reductions and other fittings.

Supported calculation codes

NextGen allows calculation according to the following standards:

Along with these, a module to calculate piping by formulae according to EN 13480 is available.Additional validations and Interoperability

International standards usually do not cover everything you need to validate in order to certify a pressure vessel. For this reason, NextGen integrates additional checks according to the most established manuals, such as Moss, Bednar, Roark, as well as additional international standards such as TEMA, WRC, ANSI, EJMA, Eurocodes or PD 5500.

NextGen is designed to fit your workflow: we support direct file import from HTRI Heat Exchanger Suite for rapid exchanger calculation and offer a dedicated interface with Nozzle PRO for advanced finite element analysis (FEA) of nozzle loads.

The software also performs verification of loads due to earthquake, wind and snow according to the most widely used codes.

Looking for a version to try?

You can download and install a fully functional version of NextGen, test it for a whole month and see if it fits your needs. Or you can ask for an online demonstration (via Microsoft Teams). Or you can do both!

Made in Europe

NextGen is made in Italy, EU. Our Vice President, Mr. Fernando Lidonnici , is Convenor of CEN TC 54 Unfired pressure vessels, WG 53 Design methods. We have a close relationship with our users all across Europe - including small and large companies, multinational corporations and Authorized Inspectors - to build together the best possibile software to calculate pressure vessels and heat exchangers according to the EN 13445 norm.

Piping can be calculated in NextGen according to EN 13480. Future developments will include calculations according to EN 12952 and EN 12953, for water tube boilers and shell boilers.

NextGen in 5 minutes

Ease of use and speed

To do complex calculations you don't need to use a complicated program. We put ease of use first: from installation to productivity takes very little time, because the software is designed to be simple, intuitive and immediate.

The design windows are consistent in their appearance, there are visual aids regarding the dimensions to be inserted, contextual help, clear and understandable error and warning messages. The final calculation report is neat and the information easy to find.

In the image: creation and validation of a cylinder is very simple. Validation occurs in real time. Clear feedback is given to obtain optimal results.

Focus on design

Our aim is to let our users be competitive on the market, by reaching the best result in terms of stability and security quicly and without wasting expensive material. From the Heat Exchanger Wizard to the Flange Designer, we hold design in high regard.

Our Usage Factor let you know not only if a component is validated or not, but also how much you're over-designing it: as usual, this happens in real time.

In the image: reducing the thickness of the tubesheet leads to an increase of usage factor, up to the point where the component becomes unstable.

Learn more about the Usage Factor, the Heat Exchanger Wizard or the Flange designer

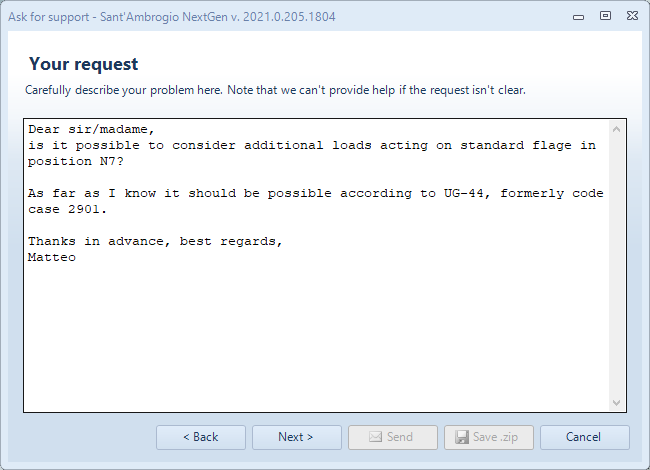

Direct Technical Support

Our users have access to a privileged support channel: you can contact our support team directly through the program and receive an answer within few hours.

No call centers or endless tickets: the people assisting you are the same engineers who develop the software. You will have direct access to real expertise to solve your regulatory and technical doubts in no time.

Learn more about our Technical Support

Continuous development

The NextGen service fee includes continuous updates to the program: we normally release 2-3 updates every year and each of these contains a long list of new features, regulatory adjustments, improvements to what is already present and corrections of issues. For maximum transparency, a list of these changes is available for each version.

Tailor-made license

Why pay for something you don't use? The NextGen license is fully customizable and allows you to purchase only the modules relevant to your business. It is always possible to extend it later by integrating new modules.

NextGen is now available also in rental form, so as to offer the widest and most flexible range of options and cover every need.

Request a complimentary trial

Try it without obligations

Request a trial version of the program today: you will be provided with a full license, lasting one month. During the trial period you will have access to our service and support guides available on this site.

If you wish, we are available for a remote demonstration via Microsoft Teams, to show you the program's features and to answer all your questions.

Request form