Formulas for calculating maximum pressures (MAWP, MAP)

One of the most frequently asked questions concerns the lack of formulas relating to maximum pressures (MAWP, MAP) in the calculation report of the components validated with NextGen.

NextGen cannot produce such formulas since the system for calculating these pressures is based on an iterative process, therefore a direct formula is not adopted.

The iterative process involves the following:

the program assumes a maximum pressure, for example 100 MPa, and checks if the component is stable with this pressure

if the component is stable, the pressure is doubled; if the component is unstable, the pressure is halved

This process continues with a series of doubling and halving until an acceptable pressure value is found.

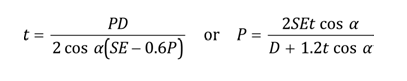

For certain components, the standards provide a direct formula for calculating the maximum allowable pressure, generally this is an equation related to that for calculating the minimum thickness.

Nonetheless, time and experience have led us not to adopt these single equations because while it is true that they quickly return a pressure value, they generally do not take into account further checks that need to be conducted and which also affect the MAWP.

For example, for the conical section of a reducer the direct formula is available in ASME, but this completely ignores what happens to the knuckle, the flare and the junctions with the adjacent cylinders, returning only the maximum pressure of the straight section. NextGen instead calculates the maximum pressure of the entire cone, including joints, considering both the conical section and any bevels and joints.

How to check the MAWP calculation?

To check the MAWP calculation, you can set it as the internal pressure of the vessel and reprint the calculation report.

Search the documentation

Customer area

Categories

Articles in this category

- EN 1092-1 flanges rating with ASME/ASTM materials

- How to visualize the test cases report of ASME PTB

- How to submit a request for interpretation to ASME

- How to submit a question to the EN agency

- When the latest edition of ASME BPVC becomes effective?

- The values printed in the materials properties summary appear to be incorrect

- Why are allowable stresses in the WRC calculation under AD 2000 so low?

- Absolute pressure or relative pressure

- Negative pressure, depressurization, differential pressure

- Formulas for calculating maximum pressures (MAWP, MAP)

- What changes in the calculation of heat exchangers in the 2023 edition of the ASME BPVC?

- List of keyboard shortcuts

- How to add a coaxial nozzle to the small end of a cone

- How to quickly reuse material or gasket that have already been set in the item

- Questions and answers related to demos and courses