PED compliance for appliances designed according to ASME

For some appliances designed according to the ASME code, in particular ASME VIII Div. 1, it is necessary to verify that these appliances comply with the safety criteria of the PED, the European pressure equipment directive.

NextGen supports this process in two key points:

- Support in choosing the allowable in compatibility with the PED

- Calculation of hydraulic test pressure according to PED

Enabling PED compliance

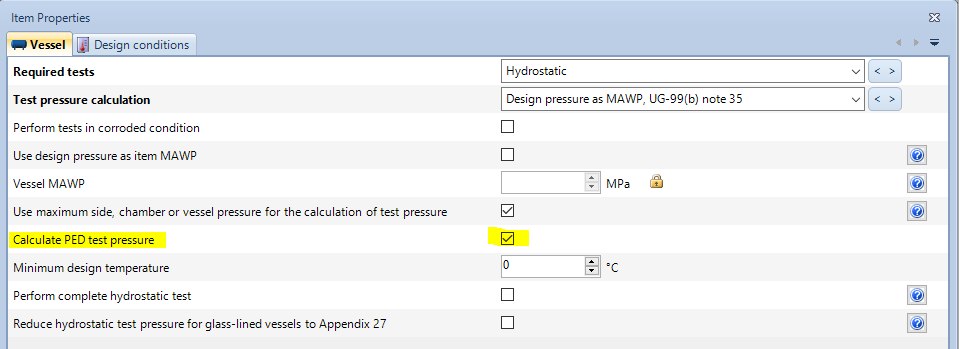

The operation can be performed via a simple flag to be set in the Item properties, in the section relating to tests:

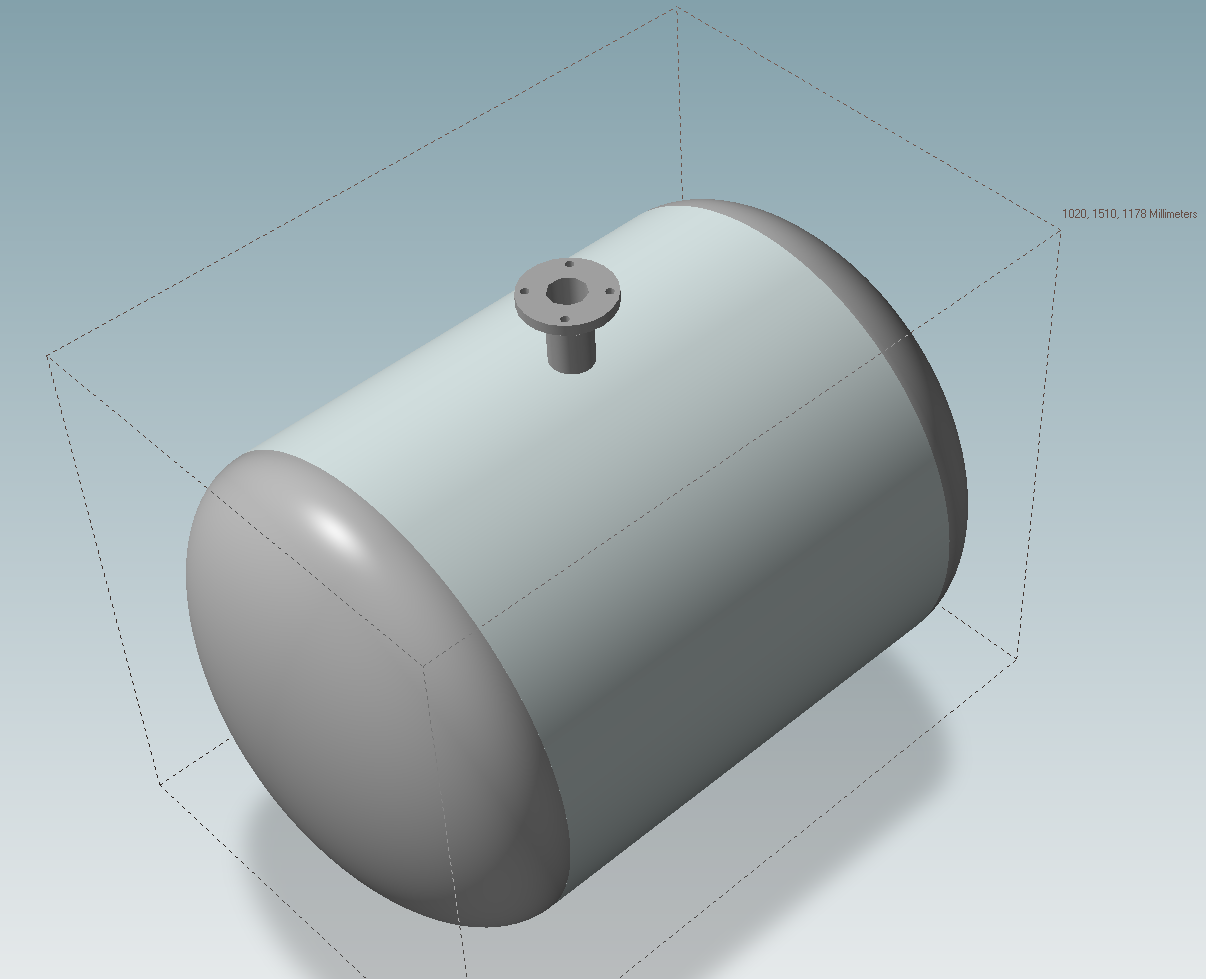

The demo item is composed of heads, main shell, nozzle and flange:

Choice of materials

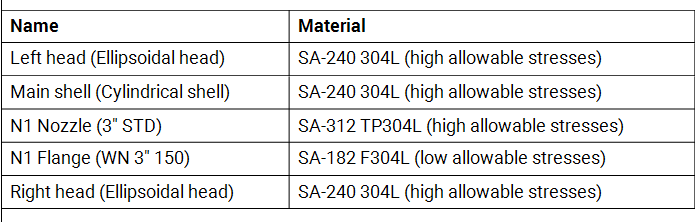

For a 304L austenitic steel construction, not considering compatibility with PED, the choice would fall on the following:

The parts under pressure which in the event of deformation would not lead to the loss of fluid (sheets, pipes) would be sized considering the highest allowables according to note G5 of the material, while the flanges would use the reduced allowables.

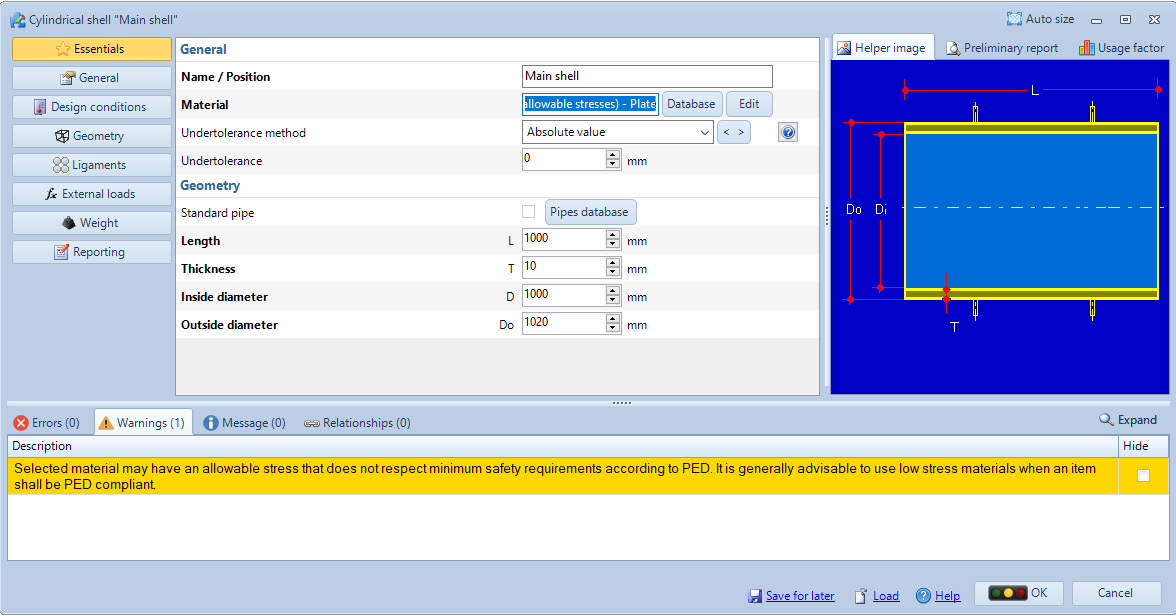

However, NextGen will show the following warning on cylinders, heads and nozzle:

Selected material may have an allowable stress that does not respect minimum safety requirements according to PED. It is generally advisable to use low stress materials when an item shall be PED compliant.

This happens due to the fact that austenitic steels in their "low allowable stress" version have an allowable calculated by ASME which is lower, therefore compliant, than the allowable according to PED. This is not the case for "high allowable stress" variants. It is therefore sufficient, to comply with the safety criteria, to use the "low allowable stress" variants for all the materials used.

The other types of steel, such as carbon steel, have an ASME admissible grade that is always lower than the PED admissible grade and therefore no particular precautions are necessary in that case.

Calculation of hydraulic test pressure

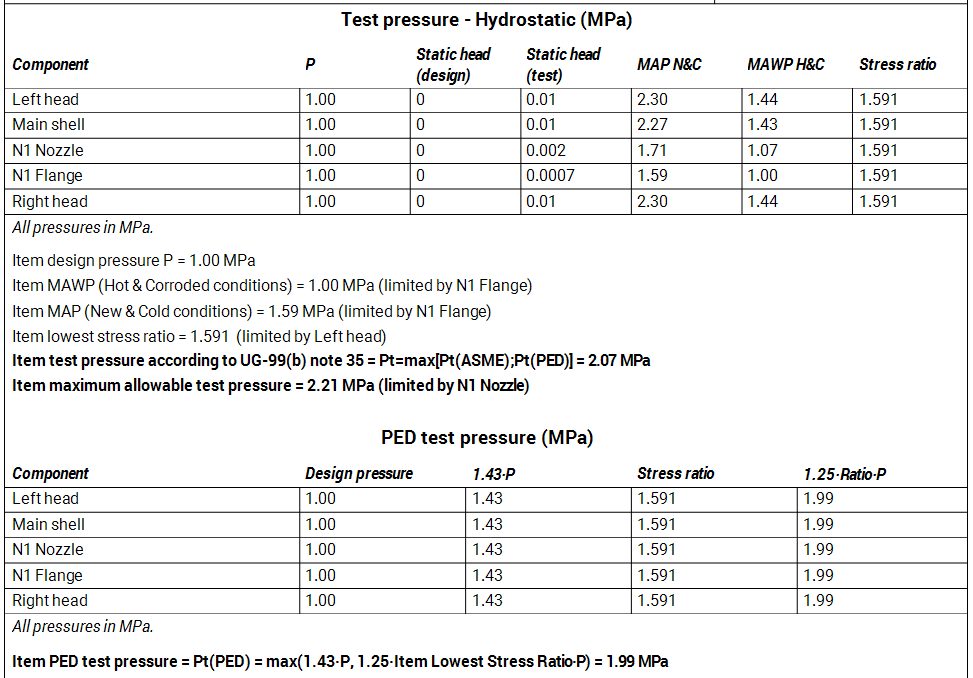

In the calculation report, in the section relating to the calculation of the hydraulic test, two distinct summary tables will be shown: one for ASME and one for PED. The ASME table will also report the maximum value between the ASME and the PED as the calculated pressure.

News archive

- Jan 29, 2025: Design a body/girth flange automatically using the Flange Designer tool

- Sep 19, 2024: How to design a vapor belt for an heat exchanger

- Feb 07, 2024: Clamp connections

- Nov 15, 2023: Vortex shedding calculation according to EN13445 Clause 22.10

- Jul 05, 2023: How to design a double tubesheet heat exchanger

- Feb 09, 2023: PED compliance for equipments designed according to ASME

- Oct 04, 2022: Using the Usage Factor function to calculate the percentage of component utilization

- Oct 04, 2022: Fatigue Analysis Screening, Method B according to ASME Section VIII div 2 Clause 5.5.2.4

- Oct 29, 2021: Design of adjacent VSR openings beyond 0.8 De of a formed head

- Sep 30, 2021: How to design an hairpin or double pipe heat exchanger

- Feb 23, 2015: Maximum Allowable Working Pressure (MAWP) and hydrostatic test pressure calculation