Material characteristics customization

One of the most requested features by our customers has always been the ability to modify one or more material characteristics like allowable, yield strength or elasticity "on the fly". NextGen already supports custom materials, which is the preferred way for all those cases when a material not available in our database is needed. In some other cases however, a client may require modified values, for instance when the target country adopts a foreign calculation code with different safety factors: for this scenario we added in our 2017.1 release the ability to modify one or more material features.

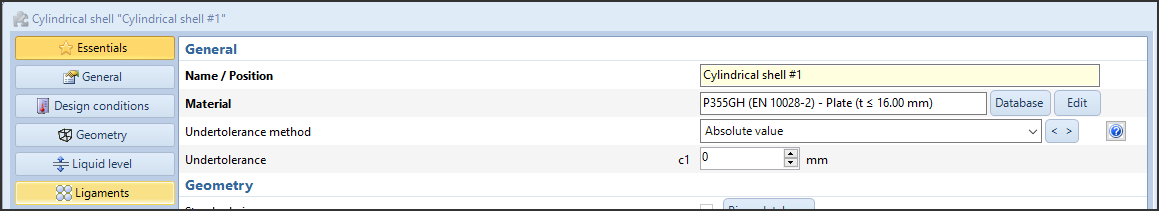

An "Edit" button is available near the well-known "Database" button used to select a material:

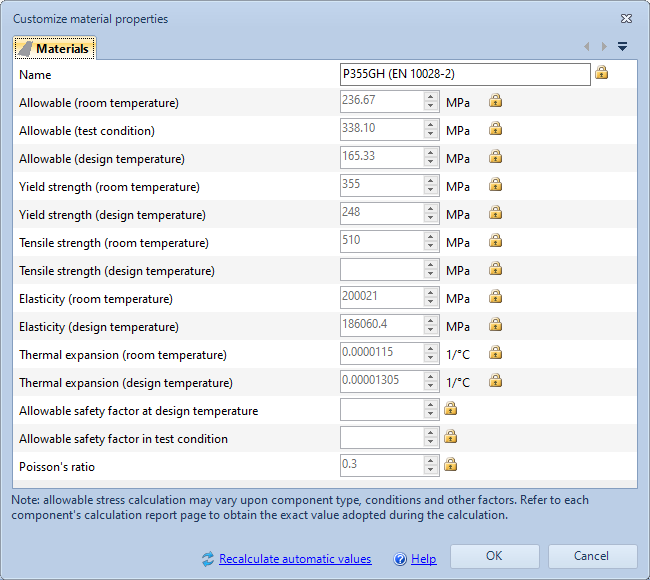

After selecting a material, clicking on the "Edit" button shows a new window where the user can overwrite common material characteristics:

In the image above, the customization of an AD 2000 material is shown. The input fields in this window may vary upon the currently selected Calculation Code

Values can be edited in a friendly interface for our NextGen users: values are automatically calculated when the padlock icon is closed; to modify this values, simply click the padlock icon and input a new value. This value will then be used in every context where calculation code in use explicitly refers to it.

The values automatically calculated and shown with the closed padlock are to be considered indicative, since they use the general rules for calculating the allowable. Certain components, in some conditions, may have different rules and actually use a different allowable. Always rely on the component calculation report to view the allowable value adopted in the calculation.

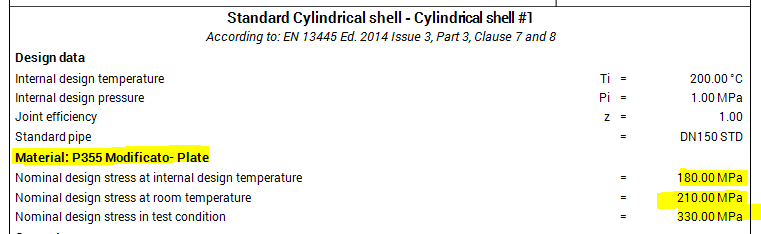

Report will show user defined data, omitting any eventual formulae.

Notes related to ASME materials customization

ASME provides all material usage data and states in ASME II Part D:

The information in the Applicability and Maximum Temperature Limits columns is mandatory. Where a material is permitted for use in more than one Construction Code, and in the SI units version of these tables, the maximum use temperature limit in these columns is critical. The temperature to which allowable stress or design stress intensity values are listed is not necessarily the temperature to which use is permitted by a particular Construction Code. Different Construction Codes often have different use temperature limits for the same material and condition. Further, values may be listed in the stress tables at temperatures above the maximum use temperature limit. These stress values are provided to permit interpolation to be used to determine the allowable stress or design stress intensity at temperatures between the next lowest temperature for which stress values are listed and the maximum‐use temperature limit listed in these columns.

Furthermore, in ASME VIII Div. 1 UG 20(c):

Design temperatures that exceed the temperature limit in the applicability column shown in Section II, Part D, Subpart 1, Tables 1A, 1B, and 3 are not permitted. In addition, design temperatures for vessels under external pressure shall not exceed the maximum temperatures given on the external pressure charts.

Before proceeding with any modification, it is recommended that the user ensures that such modifications comply with applicable regulations and are adequate for the intended use of the pressure equipment.

Before finalizing or using any calculations based on the changed properties, it is essential that the user agrees and validates the changes with the inspector or the competent authority in charge of reviewing and approving the calculations.

Notes on customizing AD 2000 materials

In AD 2000, allowable stress is calculated dividing the material characteristic K by a safety factor S. NextGen automatically calculates the safety factor S but leaves the freedom, at the user's discretion, to modify this factor for the design and test conditions.

Search the documentation

Customer area

Categories

Articles in this category

- How to create a custom material

- Material characteristics customization

- Materials set feature and its usage

- Why is an ASME material unusable at a certain temperature despite having the allowable and yield strength values?

- Why do some ASME materials lack the yield strength, tensile strength, elasticity or thermal expansion values?

- How to import an ASME VIII material from Division 1 to Division 2 or vice-versa

- Request to insert materials not available in the NextGen database