Understanding and solving validation errors

Validation errors may arise during design with NextGen. These types of errors are part of the normal work cycle with the software: the purpose of this article is to provide the user with the tools to understand and solve them independently.

The validation process

When the program has all the data required by the user to calculate a component, it proceeds with its validation. Validation is a two-step check that aims to provide the user with a series of intermediate and final values, as well as a result summarized by the traffic light icon.

Step 1: geometric validation

The first validation step is independent of the calculation code adopted and includes a geometric validation. The purpose of this validation is to understand whether the component set can be realistically represented in the 3D workspace and whether it is possible to perform the subsequent check on it.

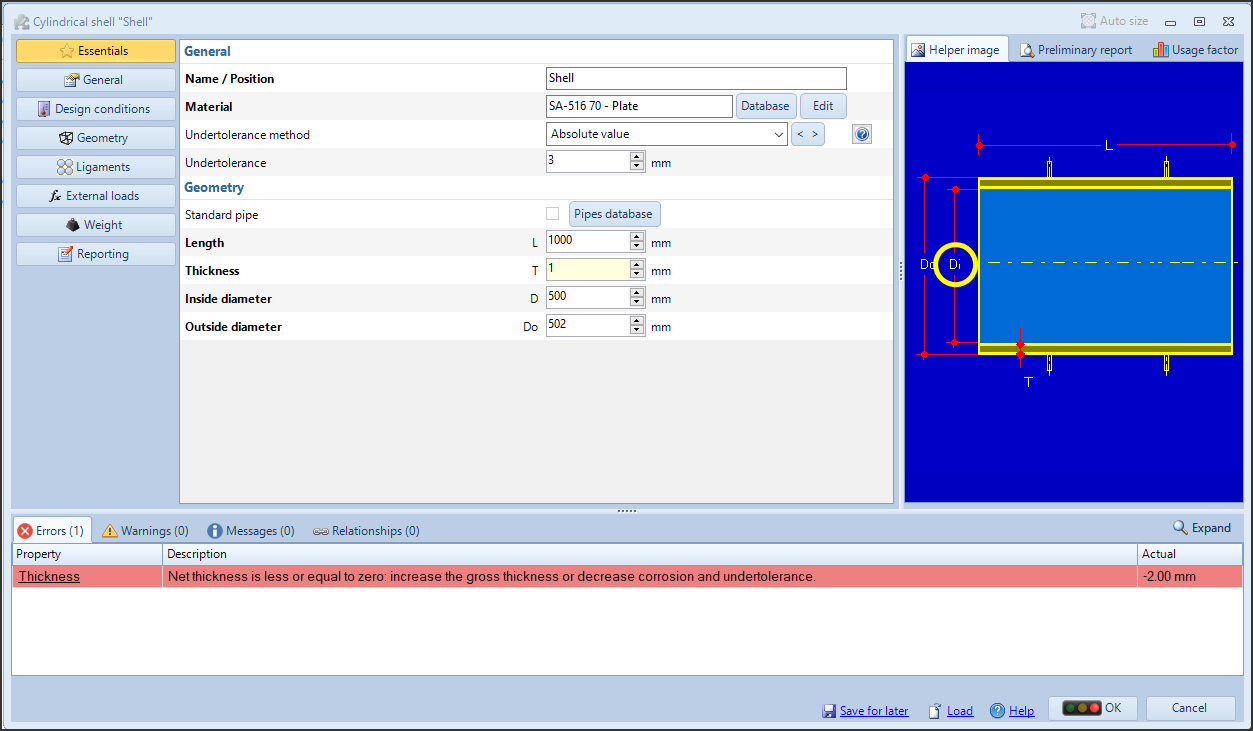

Example of a cylinder with a geometric validation error

For example, creating a cylinder with a nominal thickness of 1 mm, having set a tolerance of 3 mm, generates a geometric error that indicates to the user that the net thickness value is negative. To resolve the error, it is necessary to increase the thickness.

Geometric validation errors prevent the component design window from being closed by clicking OK, since the 3D component cannot be physically added to the workspace

Step 2: code validation

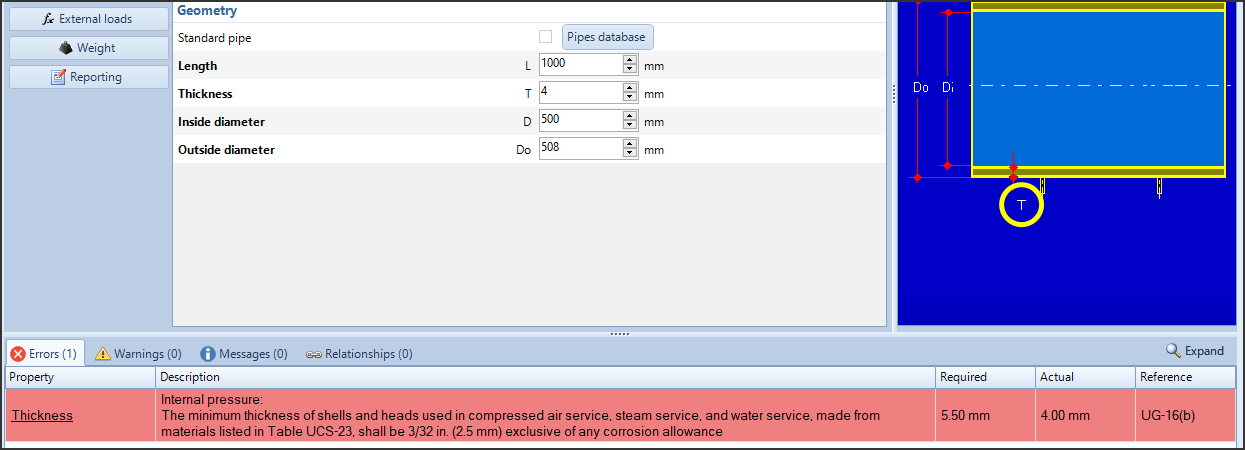

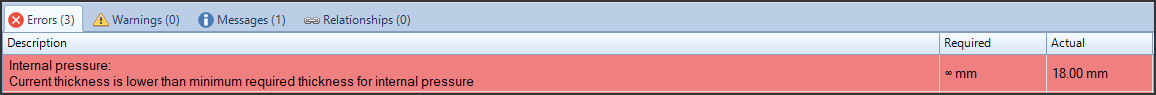

Once the first geometric validation step has been passed, the program proceeds with the application of the rules of the calculation code in use. Following the previous example, once the thickness has been increased to obtain a positive net thickness, NextGen applies the rules of ASME VIII Div. 1 and produces the following result:

Example of code evaluation of a cylinder

Here, according to UG-16(b), a steam service has been set for this calculation. NextGen detects an insufficient minimum thickness and reports it to the user.

This type of error allows the window to be closed by clicking on the OK button. It is therefore possible to keep the component in question in error status, in case you want to resolve it at a later time.

The validation table

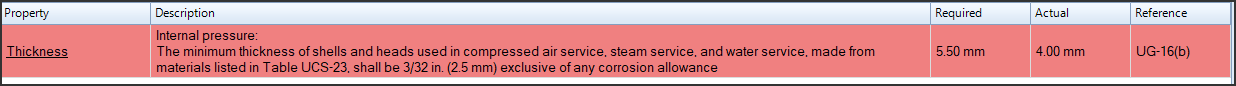

By carefully observing the validation table, you can obtain important information for resolving errors.

Property: indicates which property the error refers to. The property name is clickable, so you can position yourself directly on the value to be modified to change the calculation

Description: description of the error which, where possible, reports the exact wording present in the calculation codes

Required: the value required by the calculation to ensure that it is valid

Actual: the value currently calculated, based on the data available to the program

Reference: chapter, paragraph, formula of the regulation whose application is generating the error

Not all the data reported here are always available. In some cases, the program cannot calculate a required value, or in the case of geometric validation there is no reference to a norm paragraph.

Calculation error analysis

The most common case of validation error concerns, depending on the type of component, an insufficient thickness or a resistance lower than required.

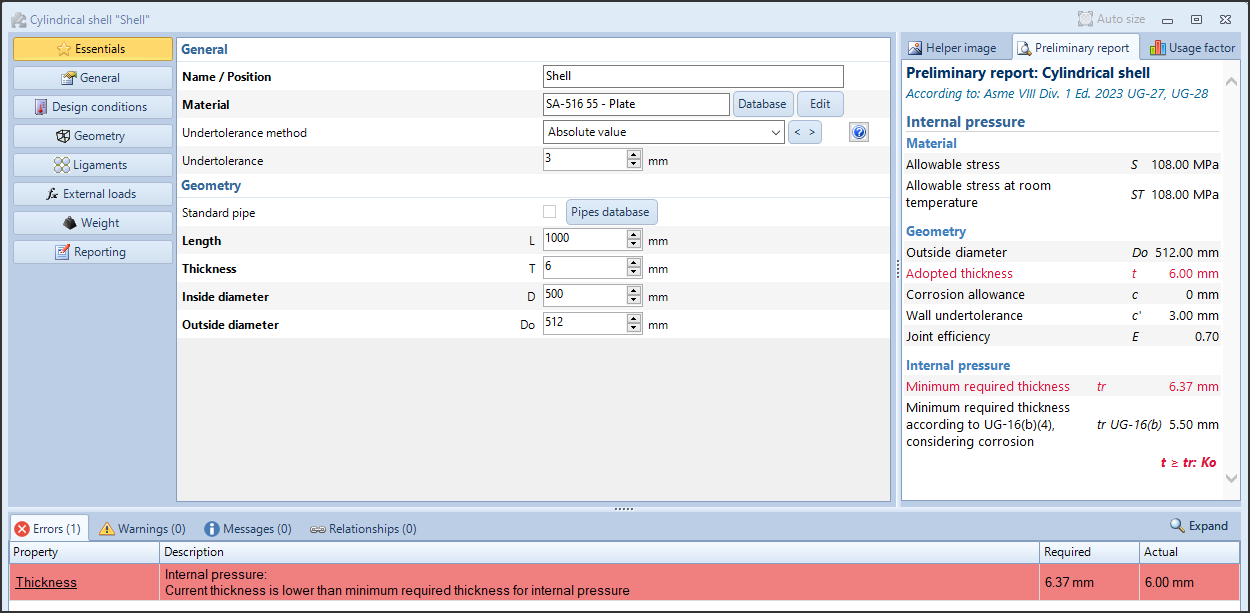

Cylinder with insufficient internal pressure thickness

The case under consideration, a carbon steel cylinder with a thickness of 6 mm insufficient to withstand a pressure of 1 MPa at 180°C, would lead as a first choice to increase the nominal thickness by 1 mm, so as to satisfy the verification.

However, observing and analyzing the calculation report can help to understand what happens and above all find alternative solutions.

We recommend experimenting with this type of approach with components whose calculation is simple and direct, such as a cylinder, and then moving on to more complex scenarios such as flanges or openings.

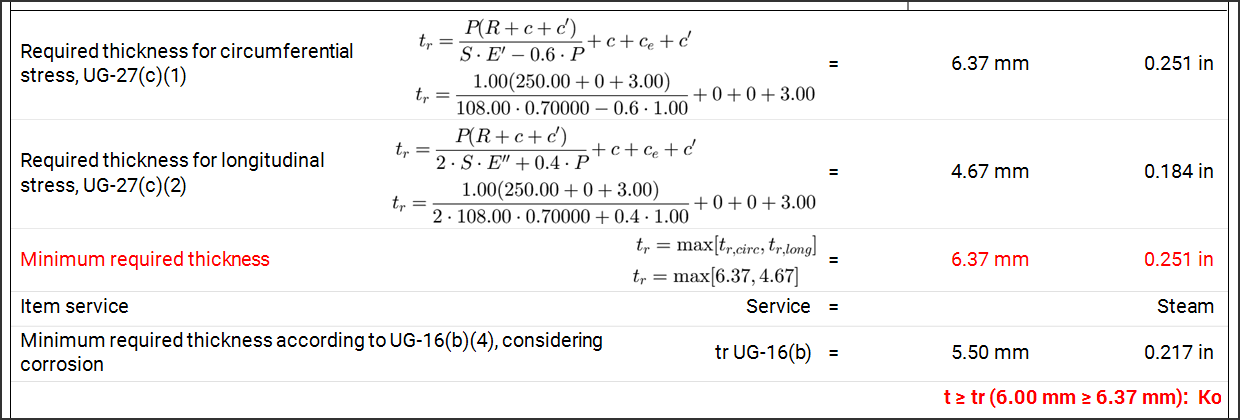

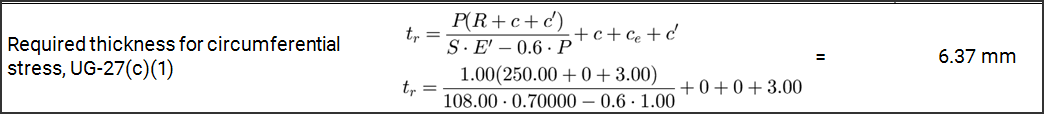

Calculation report of the cylinder with insufficient thickness at internal pressure

NextGen highlights the validation problem in red. From the reported formula, it can be seen that the minimum thickness is the highest value between two formulas. Having identified the formula that is determining this value, it can therefore also be analyzed.

The correspondence between the input values and the final output is starting to become clearer. For example, the radius R in the numerator indicates a value that, if increased, will have the effect of increasing the minimum thickness required. The pressure P intervenes in both the numerator and denominator, although to a lesser extent.

Above all, the welding efficiency is in the denominator, as is the allowable: this means that increasing these values will result in a lower minimum required thickness.

It is now evident that, in the comparison tr ≥ t, the designer can not only increase t to satisfy the calculation, but also intervene to reduce tr.

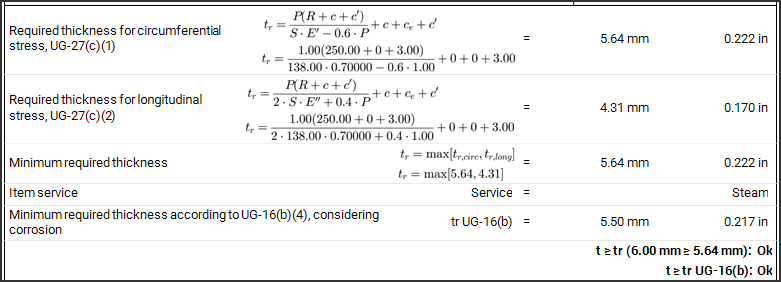

Cylinder verification satisfied

Moving from a SA 516-55 material to SA 516-70, the allowable is increased from 108 MPa to 138 MPa, satisfying the verification.

Complex error resolution (NaN, infinity)

The procedure illustrated in the previous paragraph becomes essential when dealing with more complex errors. For example, it may happen that NextGen gives a result with the value Not a Number (NaN) or infinity ± ∞.

This means that the calculation involves one or more invalid mathematical steps, such as:

square root of a negative number

division by zero

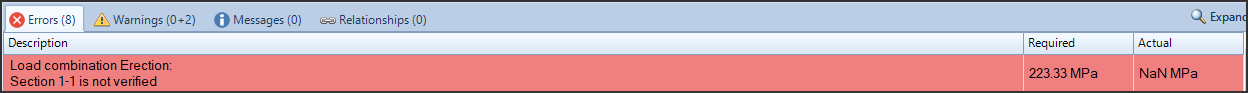

You can already tell when this happens from the design window:

Example of infinite requested value

Example of current value Not a Number

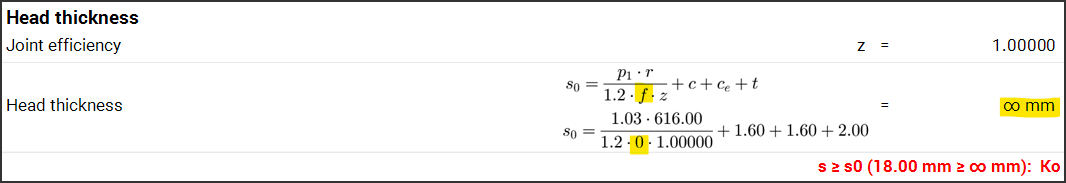

Repeating the previous procedure, we produce the calculation report and identify where the problem is.

Division by zero in calculating the minimum thickness of a bottom

The check that fails must be identified, its formula and finally the value in the formula that leads to an invalid result. In this case, it is clear that it is a division by zero and that zero is the admissible value of the bottom in use.

To resolve the error, it is therefore sufficient to intervene on the material, taking care to choose one for which it is possible to calculate the admissible value or, alternatively, specifying an admissible value manually.

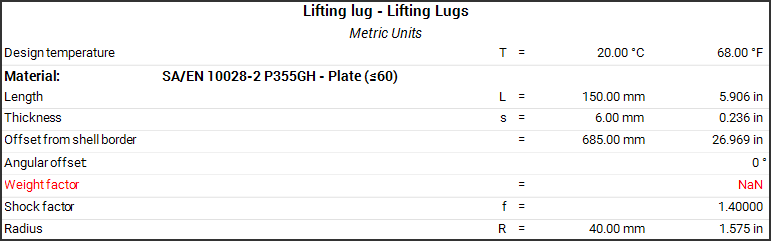

In the second case, the report highlights that NaN is the value assigned to the Weight Factor for the Lifting lug:

In this case, it is a value automatically calculated by the program; if the program does not have all the elements to calculate this value, it can produce an invalid value as in this case. Again, the user can unlock the input box and enter a manual value, so as to complete the calculation correctly.

Final considerations

In most cases, when a validation error is encountered, the procedure adopted by NextGen can be considered correct; the calculation report is the tool to adopt to understand where the failed validation comes from and therefore which input values to modify to obtain a satisfactory verification.

In rare cases, the program may fail to adopt the rules of the calculation code: if you think you have encountered this situation, you can open a support request via Ask for Support, along with a detailed numerical calculation, for example in the form of an annotated PDF or Excel sheet, which clearly shows the expected values, possibly with references to the formulas of the calculation code or the standard used and where these are calculated incorrectly by NextGen.