Fatigue Analysis Screening, Method B according to ASME Section VIII div 2 Clause 5.5.2.4

With NextGen it is possible to perform a fatigue screening procedure for projects according to ASME Section VIII div 2. The fatigue screening allows to determine if a fatigue analysis is required as part of the vessel design. If the screening is satisfied, then a fatigue analysis is not required as part of the vessel design.

In order to perform the fatigue screening, the user must perform two main operations:

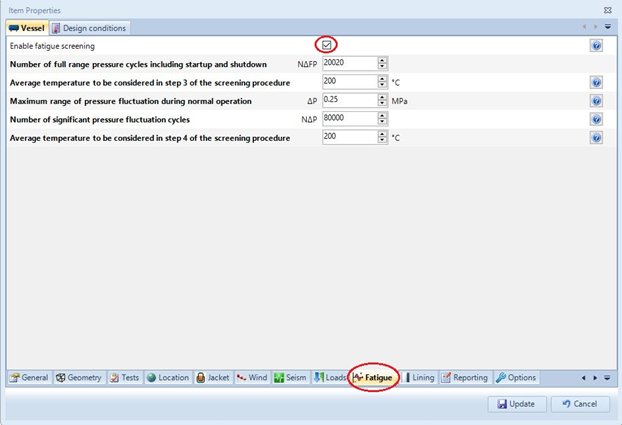

Define on Item level the inputs for step 3 and 4 of the fatigue screening procedure

Define on Component level the inputs for step 5 to 8

The definition of the Item level inputs can be done in Item properties (File > Item properties > Fatigue). Fatigue screening detail fields appear once "Enable fatigue screening" is enabled:

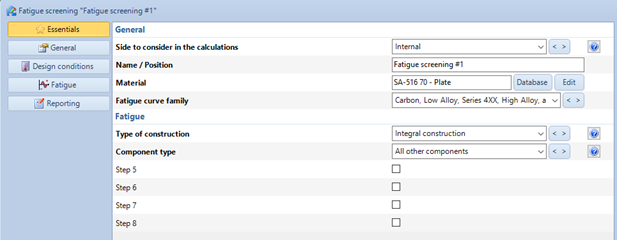

Now the user can create a “fatigue screening” component as an additional component. In the window that appears all the details on a component level shall be provided.

The creation of the “fatigue screening” component is critical, since no calculations will be made by only enabling fatigue screening. The user must specify important parameters like the material and the fatigue curve family of the material and only then will the calculations be made for the specified material. If the user wishes to perform a fatigue screening procedure for another component, he must create a new “fatigue screening” component.

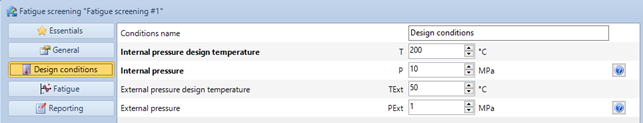

The design conditions of the Item are reported on the form, and the user shall specify whether he wants to consider the internal or the external side of the design conditions. The user may also choose to adopt design conditions different from the Item, by changing the default values in the window (that correspond to the Item design conditions).

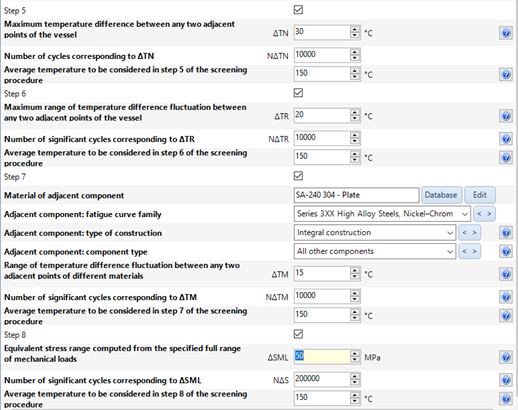

The user may choose to activate or deactivate the steps 5 to 8 of the fatigue screening procedure according to its needs.

In the example provided above all steps were activated. Almost all properties under this section have a contextual help ("?" button) that shows clarifications from the calculation code and/or how the data will be used in the calculations.

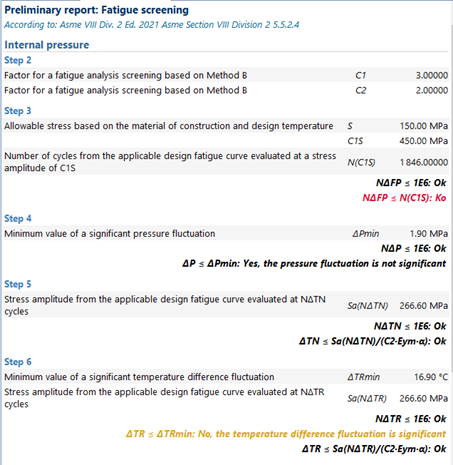

Calculation occurs in real time once all the inputs are inserted. The user can have a glance at the preliminary report for seeing the most important results of the calculation.

The full detailed calculation is described in the final report.

Search the documentation

Customer area

Categories

Articles in this category

- Design a body/girth flange automatically using the Flange Designer tool

- How to design an hairpin or double pipe heat exchanger

- How to design a vapor belt for an heat exchanger

- How to design a double tubesheet heat exchanger

- Low temperature design according to AD 2000 code

- Design of adjacent VSR openings beyond 0.8 De of a formed head

- Fatigue Analysis Screening, Method B according to ASME Section VIII div 2 Clause 5.5.2.4

- Using the Usage Factor function to calculate the percentage of component utilization

- PED compliance for equipments designed according to ASME

- Maximum Allowable Working Pressure (MAWP) and hydrostatic test pressure calculation

- Vortex shedding calculation according to EN13445 Clause 22.10

- Clamp connections

- Item revision system

- How to design supports for stacked equipments