Standard flanges and flanges according to calculation code

NextGen enables the design and calculation of flanges through two distinct approaches:

Standard flanges: These are commercially available flanges manufactured to established standards and rated for specific pressure levels. NextGen does not perform calculations for standard flanges but instead verifies that the flange's pressure rating meets or exceeds the design pressure requirements.

Code-Calculated Flanges: These flanges are designed and analyzed according to applicable calculation codes. They can be configured with either custom geometries (typically used for main body flanges) or standard dimensional specifications. For this flange type, NextGen performs comprehensive calculations in accordance with the selected calculation code to ensure structural integrity and performance compliance.

An important consideration is that each calculation code specifies which flange standards are compatible when using the standard flange approach. This means a flange can only be considered "standard" when paired with a compatible calculation code.

Cross-code compatibility is usually not permitted. For example, ANSI/ASME flanges cannot be used by rating within an EN 13445 project. Similarly, EN 1092-1 or EN 1759-1 flanges cannot be applied by rating in ASME projects, despite EN 1759-1 flanges having essentially identical dimensions to ANSI B16.5 flanges. This restriction ensures that flanges are evaluated using the appropriate design criteria and safety factors specified by their corresponding calculation codes, maintaining design consistency and regulatory compliance throughout the project.

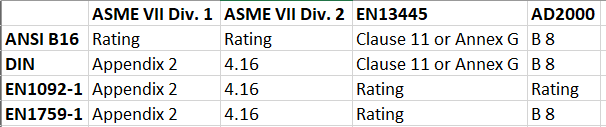

The following table shows how standard flanges are calculated when adopted in each calculation code supported by NextGen:

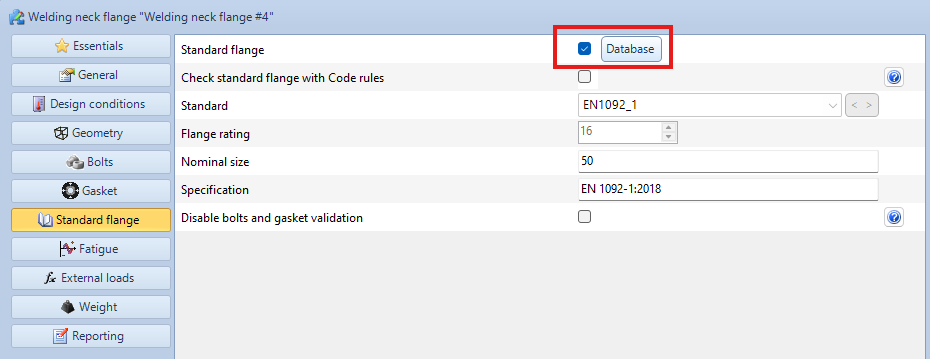

This applies to flanges selected from databases available in our software when "standard flange" option is checked:

Bolting validation is carried on only when explicitly required by the reference standard (e.g., bolts made of an "intermediate strength" material in ANSI B16.5).

Note: it is perfectly normal and very common to receive validation errors when calculating a standard flange according to a calculation code.

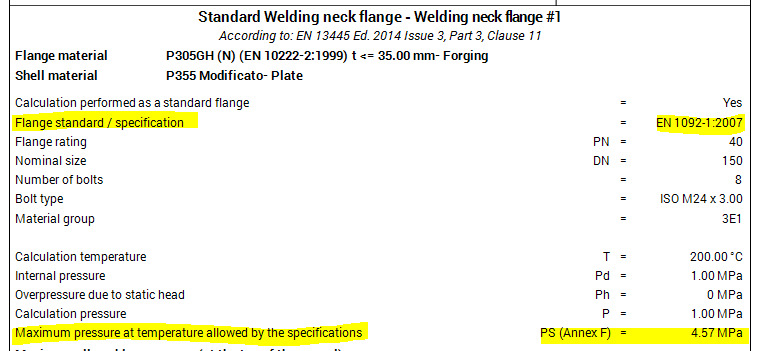

Calculation report of a standard flange is pretty simple; note the "maximum pressure allowed by specification" value.

Search the documentation

Customer area

Categories

Articles in this category

- How to create a reinforced ring opening (studding outlet flange)

- How to create a jacketed vessel

- How to use a National Annex in EN1991-1-4

- Forming Strains in ASME

- Set liquid level

- Limits on thickness for tubes and cylindrical shells in the VSR standard

- Thread calculation according to EN14359 Clause 5.5.6

- Cladding and weld overlay management

- How to design a stiffening ring against external pressure using NextGen

- Standard flanges and flanges according to calculation code

- Common mistakes when searching EN 1092-1 flange ratings

- Definition of standard tees in EN 13480

- How to design a gas cylinder with NextGen